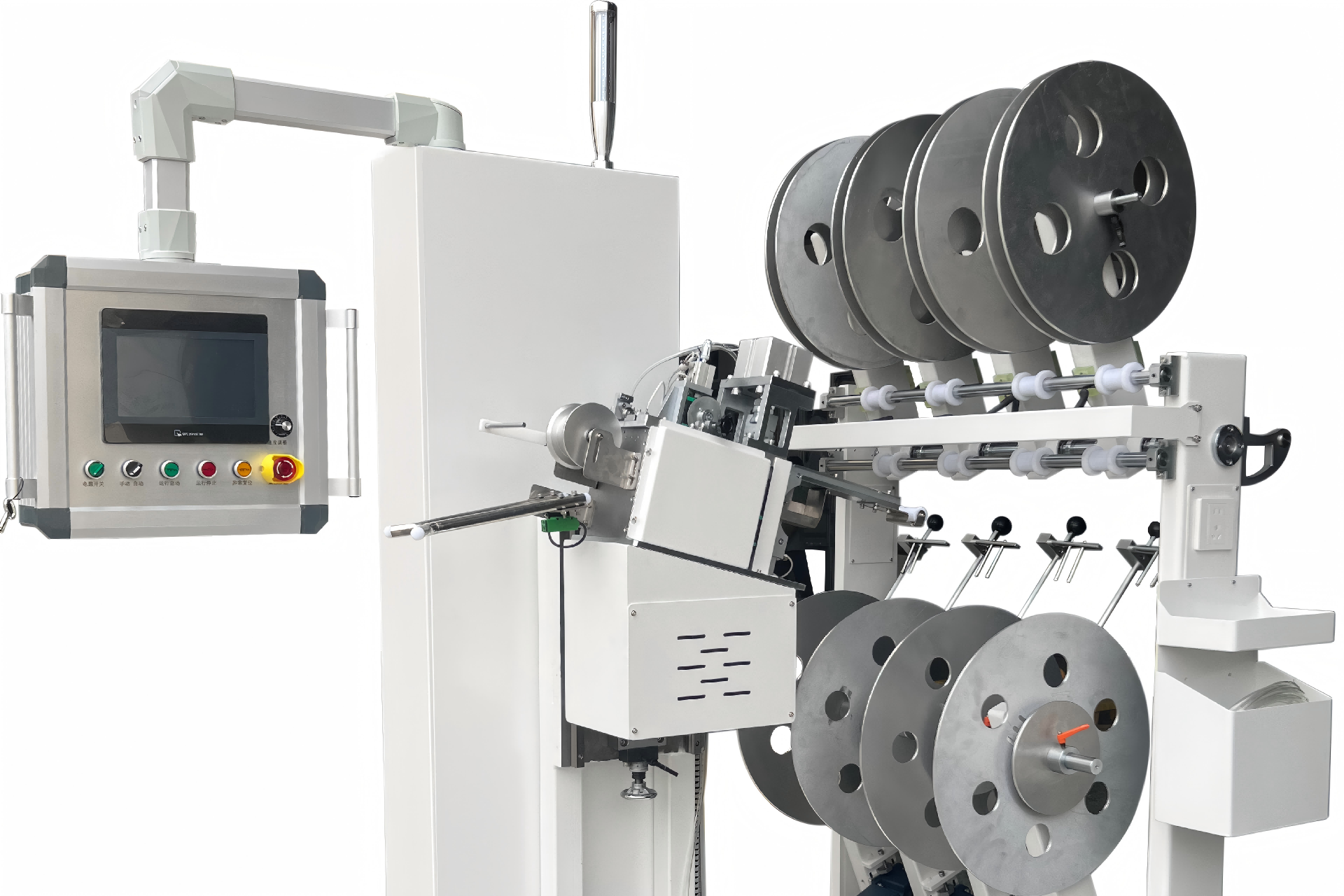

4-tray vertical automatic tray changer

4-tray vertical automatic tray changer

The automatic material receiving machine can be configured with 4 or 6 trays to realize the automatic material receiving of continuous terminal stamping. When a tray is full, it will automatically switch to the position of the empty tray to continue receiving.

The material tray can be switched automatically, saving time and improving work efficiency. After the number of terminals is reached, the sample is automatically retained and the tray is automatically changed, so that the punch press can work continuously without stopping. It can meet the needs of 1 material belt and 4 trays for automatic exchange of materials. The receiving tray has a separate power supply to prevent the wrong operation during winding and cause inconsistent receiving direction. The tray change adopts servo motor + precision screw standard transmission to meet the precise positioning size when changing the tray. The paper belt is equipped with a tension control device. The paper break sensor adopts a guide wheel encoding disk structure, and the paper belt break position can still be identified when it is in the material tray.