Customizing Efficiency - Why You Need a Non-standard Automatic Material Feeding Machine

2025-07-15

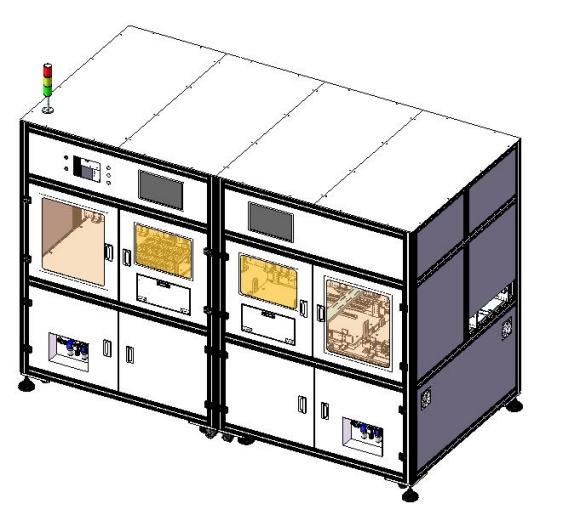

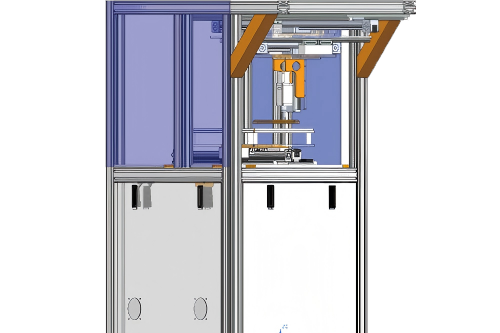

What Is a Non-standard Automatic Material Feeding Machine?

In modern industrial automation, non-standard automatic material feeding machines are playing a crucial role in boosting productivity. These are customized material handling systems that are tailored for specific production lines, especially when standard feeding equipment just won’t cut it.

Unlike traditional feeders, non-standard models are designed based on:

-

The shape, size, and weight of your materials

-

The speed and rhythm of your assembly process

-

Complex feeding sequences in multi-station automation

Whether you’re dealing with fragile parts, irregular components, or high-volume requirements, customized feeding machines deliver accuracy, reliability, and flexibility.

Why Standard Feeders Aren’t Always Enough

Let’s face it—standard solutions don’t always solve complex challenges. If you’ve ever had to constantly tweak or babysit your feeding system just to keep it working, you know what we’re talking about.

Here’s the thing: as your manufacturing needs grow, it makes sense to upgrade to non-standard feeding automation that fits your production like a glove.

Benefits include:

-

Seamless integration with existing equipment

-

Reduced downtime due to better part compatibility

-

Higher throughput with consistent part delivery

Actually, once you try a custom feeder, you’ll probably never wanna go back.

Applications in Diverse Industries

Non-standard automatic material feeding machines are widely used in:

-

3C electronics

-

Automotive component assembly

-

Medical device production

-

Hardware and fastener packaging

-

Battery and energy storage systems

Because these industries deal with precision and speed, off-the-shelf feeders just won’t do. A tailored solution ensures zero jamming, smooth transitions, and long-term stability.

Why Choose a Chinese Manufacturer?

Working with an experienced China-based manufacturer gives you the upper hand. Not only are costs competitive, but you also get:

-

Full customization based on your drawings or samples

-

On-site support and commissioning

-

End-to-end integration with control systems

-

Fast delivery to the U.S.

One of the reason why so many U.S. factories cooperate with Chinese suppliers is the combination of innovation and affordability.

Final Thoughts: Make Your Feeding Process Smarter

If you’re struggling with inconsistent part delivery, excessive labor, or equipment mismatches, it’s time to consider a non-standard automatic material feeding system. Custom automation isn’t a luxury—it’s a long-term investment in productivity.

Reach out to a reliable Chinese feeding machine supplier and explore how a customized solution can supercharge your workflow.