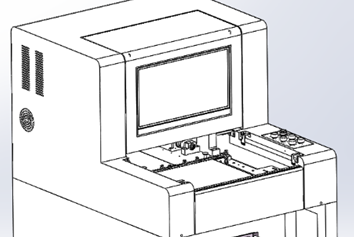

Online inspection equipment 2D AOI TU610

TU610 uses a 500w high-definition camera and RGB-LED light source to capture high-precision images on PCB boards, presenting unprecedented details. Equipped with new inspection software, it combines efficient and stable defect detection capabilities with easy programming features, making it the best solution for online AOI.

1. Online AOI with high performance

TU610 uses a 500w high-definition camera and RGB-LED light source to capture high-precision images on the PCB board, presenting unprecedented details. Equipped with new detection software, it combines efficient and stable defect detection capabilities with easy programming features, making it the best solution for online AOI.

2. High-precision motion platform-stable, simple and easy to maintain

The motion mechanism adopts a high-precision lead screw guide module, the equipment has high motion accuracy, simple structure, stable system and easy maintenance.

3. Simple, intuitive, intelligent and comprehensive program production process

The new intelligent programming and the use of automated component library greatly shorten the programming time.

4. Reliable bending plate compensation technology

Adopting the whole-plate statistical compensation method, real-time measurement and dynamic compensation of plate bending, providing the most reliable detection results.

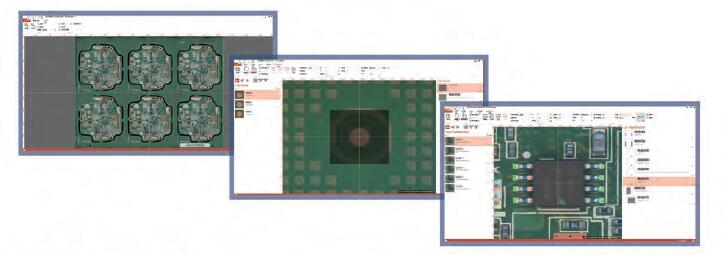

5. Seamless splicing of whole-plate images

Processing after splicing the whole plate, whole-plate calculation, real-time CAD data adjustment of the whole plate, import and export of whole-plate images

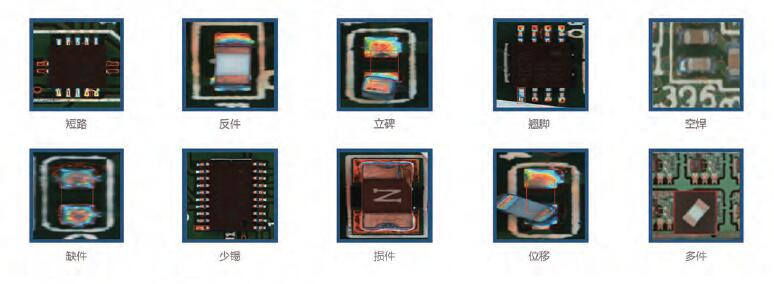

6. Efficient and stable detection results

TU610 adopts efficient and stable algorithms such as color space algorithm, contour analysis technology, OCR/OCV character recognition, machine learning, and intelligent splicing, with few misjudgments, and can perfectly detect defects such as missing parts, offset, side-standing, monumental, reverse, polarity, wrong parts, solder joints, missing pins, tinning, and text

7. Data statistical analysis tool (SPC)

Through test data collection, various data reports can be quickly and effectively counted, and users can be assisted in effective analysis to improve process capabilities; and data reports can be received and generated through various mobile data terminals;

8. Production line solution

Offline programming system

This system can be used to adjust and fine-tune the detection algorithm for pre-scanned images, and can provide timely feedback. The completed program can be uploaded to the online inspection machine to achieve high stability and high precision detection. Feedback system TU610's SPC can connect to the detection data in the SPI and AOI systems, and timely perform detection monitoring and analysis, and feedback to the detection system to find problems and implement solutions, ultimately maximizing the production yield.