Why Do Modern Cars Need an Automatic Assembly Line for Their Controllers?

2025-10-14

Have you ever wondered how today’s cars manage to react so quickly — from braking in milliseconds to adjusting the temperature automatically? Behind this magic is something small but mighty — the automobile controller. And guess what? Most of these controllers are now produced on an automatic assembly line instead of by hand.

The Role of Automobile Controllers

Automobile controllers are like the “brains” of your car. They manage electronic systems such as engine performance, lighting, air conditioning, and even advanced driving assistance systems (ADAS). As cars become smarter, the number of controllers in each vehicle keeps increasing.

Why Manual Assembly Is No Longer Enough

In the past, assembling controllers was a labor-intensive job. Workers had to handle dozens of delicate components, which often led to inconsistencies or small errors. But as car technology got more complex, these tiny mistakes became costly — a single defective chip could affect the entire system.

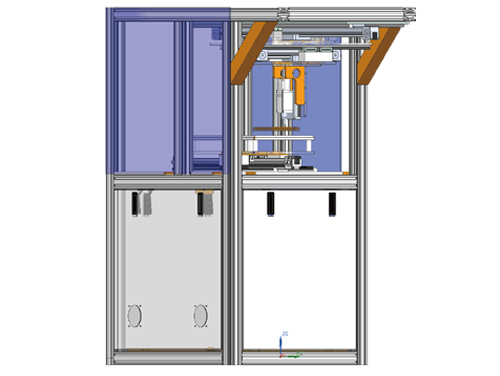

That’s why many manufacturers switched to automatic assembly lines. These systems handle delicate work with robots, sensors, and precise positioning that humans simply can’t replicate.

The Power of Automation

An automobile controller automatic assembly line ensures consistent quality, faster production, and safer operation. Every controller is tested automatically during assembly, which means fewer defects and greater reliability.

It’s kinda cool when you think about it — the machines building the brains that run other machines!

Looking Ahead

Automation isn’t replacing people; it’s improving the entire workflow. Skilled technicians now supervise and optimize these lines instead of manually assembling components.

Next, let’s dive deeper into how this automation actually works in real production — that’s exactly what we’ll explore in the next article.