Why Is CCD Detection Equipment Critical for Electronics Manufacturing?

2025-09-09

Electronics manufacturing has become more complex than ever. With smartphones, computers, and electric vehicles requiring smaller and more precise components, the pressure on manufacturers to deliver flawless products is intense. So, where does CCD detection equipment fit into this challenge? Let’s take a closer look.

The Role of CCD Detection in Electronics

In the electronics industry, a tiny defect can ruin an entire batch of products. Scratches, soldering errors, or missing parts often slip past the human eye. That’s why CCD detection systems are now being widely adopted.

These machines use high-resolution cameras and vision software to automatically scan each product. They don’t get tired, they don’t miss small flaws, and they work at lightning speed.

From Manual Work to Automated Precision

Traditionally, factories relied on manual inspection. But as product complexity grew, this method became unreliable. Workers can easily overlook microscopic defects, especially during long shifts.

By contrast, CCD inspection equipment ensures:

-

100% full inspection instead of sampling

-

Consistent detection results

-

Improved traceability with digital data

This shift doesn’t just improve quality—it saves costs by reducing rework and waste.

Benefits Beyond Quality

CCD detection equipment offers more than defect spotting. It provides:

-

Real-time feedback to adjust production processes

-

Higher throughput by reducing inspection time

-

Confidence in meeting international quality standards

These advantages make it easier for manufacturers to build trust with global buyers and win long-term contracts.

Why Choose a Chinese Manufacturer?

Many electronics companies now partner with Chinese CCD detection equipment suppliers because of their strong balance between price and technology.

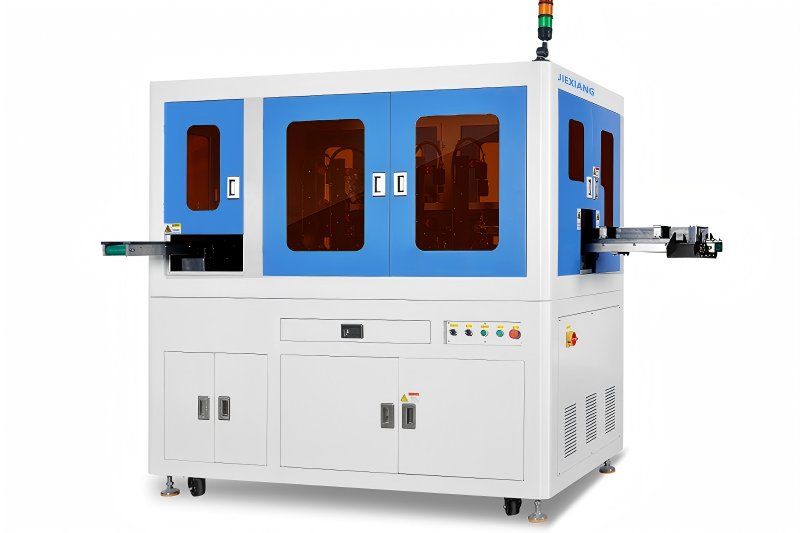

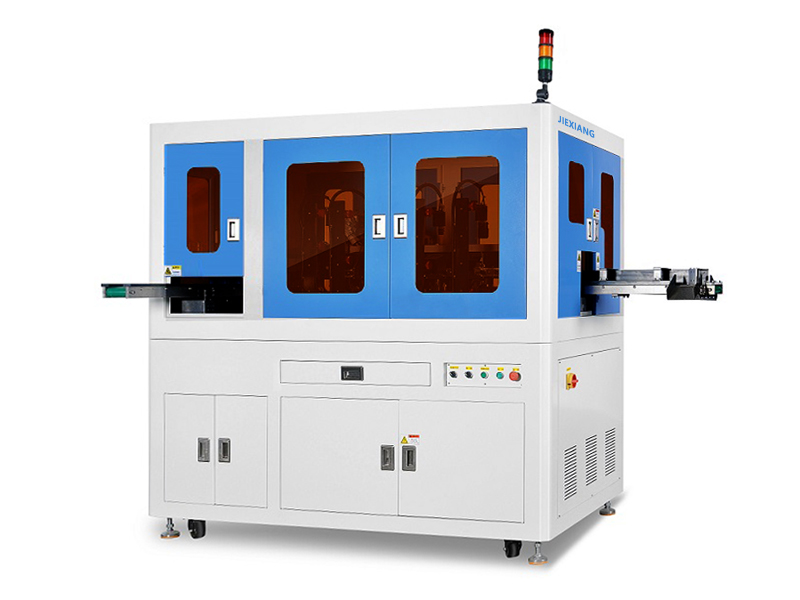

Companies like Kunshan Jiexiang Industrial Equipment Co., Ltd. specialize in providing customized CCD inspection solutions tailored to electronics, semiconductors, and lithium battery industries. Their combination of advanced R&D, international experience, and responsive support makes them a trusted choice.

For electronics manufacturing, investing in CCD detection equipment is no longer optional—it’s essential. If you want to reduce defects, cut costs, and improve competitiveness, automated vision inspection is the way forward.