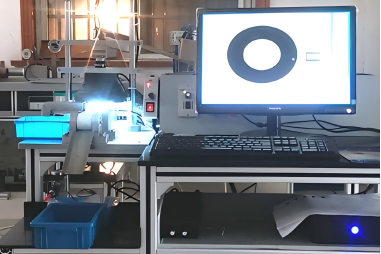

AOi automatic optical inspection equipment

2025-05-15

AOi automatic optical inspection equipment is a high-tech product that can quickly and accurately detect various defects such as short circuits, open circuits, solder joints, etc. during the manufacturing process of PCB, BGA, chips, etc. The equipment uses advanced optical imaging technology, equipped with high-definition cameras and advanced algorithms, which can identify defects in real time and classify and record them, thereby providing efficient detection solutions for production lines and greatly improving the efficiency and quality of the manufacturing process.

AOi automatic optical inspection equipment has many advantages, such as fast detection speed, high accuracy, and no need for human intervention. Through automatic optical imaging, the equipment can perform comprehensive inspections without destroying the product. At the same time, the equipment is also equipped with an intelligent operation interface and an automated management system, making the operation simpler and more convenient. In addition, the equipment has high flexibility and versatility, and can be applied to a variety of PCB, BGA, chip manufacturing processes, etc. to meet the needs of different production lines.

In short, the application of AOi automatic optical inspection equipment not only improves the efficiency and quality of the manufacturing process, but also saves a lot of manpower and material costs for enterprises. We believe that in the future, with the continuous development and promotion of the equipment technology, it will become an indispensable high-precision inspection equipment in the manufacturing industry, helping enterprises to achieve production automation and efficiency, and promote the development of the manufacturing industry.

Application field of AOI machine vision inspection system

The application range of visual inspection automation equipment is wide. The main test items of visual inspection automation equipment are dimension inspection, defect detection, etc., which can be used in many industries. Specific visual inspection needs to correspond to the needs:

1. Battery product inspection: inspection of appearance defects such as foreign matter, scratches, indentations, bad tabs, contamination, corrosion, pits, tab burns, bad inkjet printing, blurred characters, etc. of battery products;

2. PCB circuit board inspection: inspection of PCB circuit board product appearance, size, pins and patches, as well as integrity inspection of solder joints, wrong directions, etc.;

3. Precision component inspection: measurement of length, width, height, diameter and other dimensions of precision components such as screws, bearings, gears, etc., inspection of surface defects such as scratches, nicks, defects, etc.;

4. Electronic component inspection: measurement of dimensions of connectors, capacitors, resistors, etc., PIN Needle deviation, deformation, shortage and other defects, printed character detection, etc.;

5. Food packaging inspection: food packaging appearance integrity inspection, barcode recognition, sealing inspection; beverage sorting and color selection, liquid inspection, production date, shelf life character recognition; empty bottle breakage and cleanliness inspection on the filling line, etc.;

6. Medical packaging inspection: length, height, diameter and other dimensional measurements of medical plastic bottles and glass bottles, damage, black spot and other defect detection;

7. Textile and clothing accessories inspection; textile and clothing accessories (such as metal buttons, plastic buttons, etc.) dimensional measurement, appearance defect detection and label character detection, etc.