Machine Vision Surface Defect Detection

2025-05-15

Surface defect detection technology is a non-contact, non-destructive automatic recognition technology. It is an effective way to achieve automation, intelligence and precision control of machinery and equipment. It has the advantages of reliability, wide bandwidth response coverage, long-term operation under harsh conditions and high efficiency. The machine vision inspection system obtains the surface image of the product through the appropriate light source and image sensor (CCD camera), and uses the corresponding image processing algorithm to obtain the characteristic information of the image, and then accurately locates, identifies, classifies, statistics, stores, and checks the surface defects based on the characteristic information.

The basic structure of the visual inspection system software of the visual system surface: mainly includes image collection control module, image processing control module, image analysis control module, database management and industrial touch screen control module.

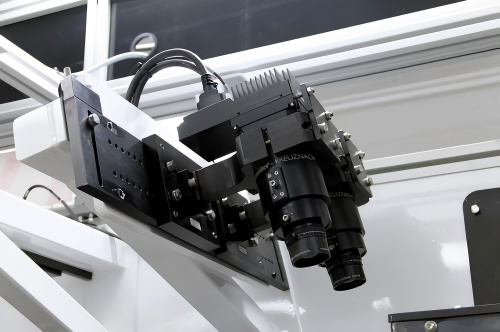

The image collection control module is composed of industrial lens, industrial camera, light source and clamping device, etc., and has the function of collecting product surface images. In the illumination of the light source, the three-dimensional image of the product surface is imaged on the camera sensor through the industrial camera. The light signal is first converted into an electronic signal, and then converted into an analog signal that can be processed by the computer. At present, industrial-grade cameras are mainly cameras based on CCD or CMOS processing chips. CCD is the most commonly used image sensor in current visual systems.

The light source of the visual system directly affects the image quality. It is used to get rid of the surrounding influence, ensure the image reliability, and obtain the image with the highest saturation. At present, the more commonly used light sources are halogen headlights, fluorescent tubes and light-assisted tubes (LEDs). LED light sources are widely used due to their small size, low power loss, fast response time, pure color, reliability, uniformity, and convenient integration.

The lighting system composed of light sources can be divided into bright field lighting and dark field lighting, structured lighting and frequency flash lighting according to the lighting method. The main and dark fields mainly refer to the positional relationship between the camera and the light source. The main lighting refers to the camera directly reflecting light to the target. The side distribution of the general camera and the light source is convenient for installation. The characteristic of dark field lighting is that the camera indirectly receives the diffuse light of the light source on the target. Generally, the camera and the light source are distributed on the same side, and a negative color image can be obtained. Structured light lighting adjusts the three-dimensional information of the object to be measured by projecting a grating ruler or a linear light source onto the object to be measured. Frequency flash lighting is to irradiate a single pulse of high-frequency light onto the object. The camera must be synchronized with the light source to take pictures.

The image processing module mainly includes image denoising, image enhancement and restoration, visual detection and elephant segmentation. The on-site environment, CCD image photoelectric conversion, transmission circuit and electronic components will reduce the image quality, thus causing image noise that may have a negative impact on image processing and analysis, so the image needs to be pre-processed to remove the noise. Image enhancement is an image processing method that aims to provide image applications, focuses on all or part of the image's features, makes the initially unclear image clear or highlights interesting special features, expands the differences between the characteristics of different objects in the image, suppresses uninteresting features, and thus improves image quality, rich information, and enhances image representation and recognition effects.

Image restoration is the process of reconstructing or repairing a poor quality image using computer processing. Image restoration usually uses the same method as image enhancement, but to see the results of image enhancement, the following steps must be performed: Image restoration uses prior knowledge of the degradation process to try to restore the original color of the degraded image. For example, removing additive noise, restoring motion blur, etc. The purpose of image segmentation is to segment the image's small elephant area so that the next step can be carried out.