Multifunctional Deburring Machine vs. Traditional Deburring: Which One Wins for Your Factory?

2025-08-12

When it comes to deburring and surface finishing, manufacturers face a big choice: stick with traditional methods or invest in a multifunctional deburring machine. So, which option really gives you the best return on investment?

Let’s break it down.

What Is Traditional Deburring?

Traditional deburring often involves:

-

Manual filing and sanding

-

Handheld power tools

-

Single-purpose machines for grinding or brushing

While it works for small-scale production, it’s time-consuming, labor-intensive, and can lead to inconsistent results.

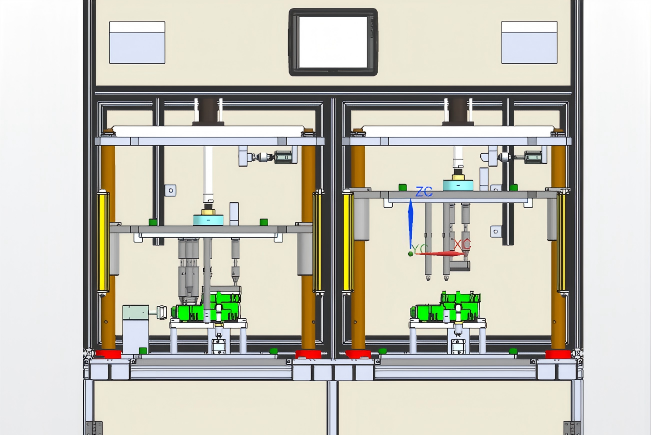

What Makes a Multifunctional Deburring Machine Different?

A multifunctional deburring machine can perform:

-

Edge rounding

-

Burr removal

-

Oxide cleaning

-

Surface polishing

...all in one pass, with consistent precision.

This integration means:

-

Higher efficiency

-

Lower labor costs

-

Better quality control

Performance: Speed and Consistency

Traditional methods:

-

Slower processing speeds

-

Quality depends on operator skill

Multifunctional machines:

-

Fast, automated processing

-

Consistent results regardless of batch size

For large production runs, automation is the clear winner.

Cost Over Time

At first glance, manual deburring may seem cheaper. But when you factor in:

-

Labor wages

-

Rework costs

-

Downtime

…the multifunctional machine often pays for itself within months.

Flexibility for Different Materials

From stainless steel to aluminum, copper, and brass, multifunctional machines can handle multiple materials without changing setups—perfect for high-mix manufacturing.

Why Many Buyers Choose Chinese Suppliers

Global buyers, especially in the U.S., increasingly source from Chinese multifunctional deburring machine manufacturers because they offer:

-

Custom-built solutions

-

Competitive pricing

-

Strong after-sales support

-

Proven export experience

Kunshan Jiexiang Industrial Equipment Co., Ltd. is one such trusted supplier, delivering high-performance deburring systems worldwide.

If you want higher speed, better consistency, and long-term savings, multifunctional deburring machines win hands down.

The only reason to stick with traditional methods is if your volume is extremely low or your products don’t require precision finishing.