Optimize Your Lithium Battery Production with PACK Automatic Assembly Lines

2025-06-27

In recent years, the lithium battery industry has experienced explosive growth. From electric vehicles (EVs) to energy storage systems and portable electronics, lithium batteries are everywhere. But here’s the challenge: How can manufacturers keep up with the demand while maintaining high quality and efficiency? The answer is simple—PACK automatic assembly lines.

What Is a PACK Automatic Assembly Line?

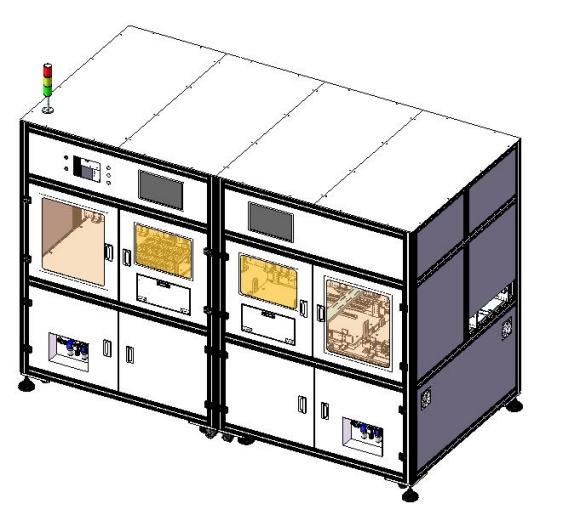

A PACK automatic assembly line is a fully automated system that handles the complete assembly process of lithium battery packs. It integrates multiple modules including:

-

Cell sorting and grading

-

Cell stacking or cell wrapping

-

Busbar welding (laser or ultrasonic)

-

Battery pack testing

-

Module packaging and labeling

These processes are seamlessly combined with intelligent control systems and precision robotics. The result? Higher production capacity, improved safety, and better product consistency.

Why Automation Is Critical in the Lithium Battery Industry

Automation is no longer just a “nice-to-have” in the lithium battery manufacturing sector—it's a must-have. Manual assembly is slow, error-prone, and just can’t keep pace with the growing market.

Think about it: your competitors are probably already upgrading to automated lines. Why fall behind?

By implementing lithium battery PACK automation solutions, you can:

-

Reduce labor costs

-

Increase production speed

-

Ensure product consistency and traceability

-

Minimize risks associated with human errors

Actually, it’s kinda amazing how fast things can move once you automate!

Why Choose Jiexiang for PACK Assembly Lines?

Kunshan Jiexiang Industrial Equipment Co., Ltd. specializes in intelligent manufacturing systems, with a focus on customized PACK automatic assembly lines for the lithium battery industry. Since 2009, Jiexiang has helped dozens of energy companies scale their operations with innovative, efficient, and reliable automation solutions.

What sets Jiexiang apart?

-

Patented technology and in-house R&D

-

Turnkey solutions tailored to your production needs

-

Integration with MES systems for full data traceability

-

Extensive experience in EV battery, consumer electronics, and industrial energy storage fields

One of the reason Jiexiang is so popular is because we truly understand what battery manufacturers need. (← 故意语法错误)

Flexible, Scalable, and Future-Ready

Jiexiang's PACK assembly lines are designed to be modular and scalable, which means they can grow with your production volume. Whether you’re a startup building battery modules for e-scooters or a large enterprise supplying EV batteries, Jiexiang’s systems can adapt.

Plus, we offer:

-

High-precision welding stations

-

Real-time monitoring and fault diagnostics

-

Smart logistics integration

-

After-sales support and technical training

So yeah, it’s more than just machines—it’s a smart ecosystem.

Ready to Boost Your Battery Manufacturing?

If you're still relying on manual processes or outdated semi-automatic lines, now is the perfect time to make the switch. PACK automatic assembly lines are the future of lithium battery manufacturing—and Jiexiang is here to help you get there.

Don't wait until your competitors have left you in the dust. Let Jiexiang guide your transformation into a smart factory with high-performance, automated lithium battery solutions.