What Is Offline AOI Inspection Equipment and Why Does Your Factory Need It?

2025-08-19

In today’s competitive manufacturing world, quality control is not optional—it’s essential. But many factories still struggle with inconsistent inspections, human error, and rising labor costs. That’s where offline AOI inspection equipment comes in.

So, what exactly is it, and why should your factory consider investing in it? Let’s dive in.

What Is Offline AOI Inspection Equipment?

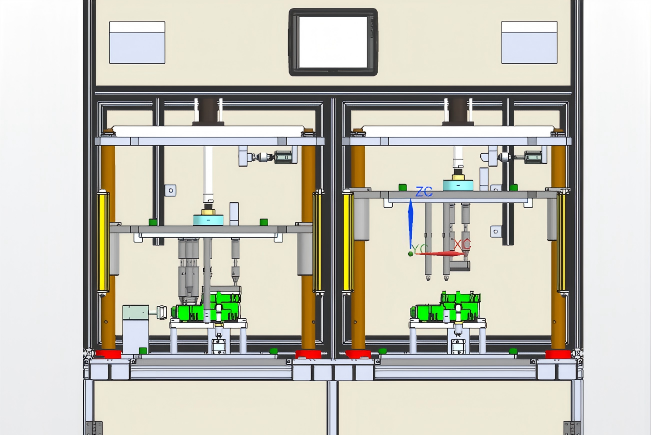

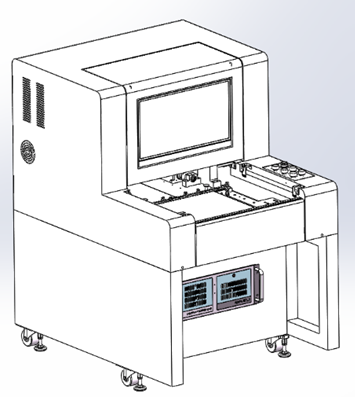

AOI stands for Automated Optical Inspection. Unlike online AOI systems that are fixed on production lines, offline AOI inspection equipment is more flexible:

-

Operators can take samples or batches off the line

-

Place them into the AOI system

-

Perform high-speed, high-accuracy visual inspections

This makes it perfect for:

-

Electronics assembly (PCBs, semiconductors)

-

Battery pack inspection

-

Automotive electronics

-

Precision components manufacturing

Why Choose Offline Instead of Online?

You might be wondering: why not just use online AOI systems? The answer comes down to flexibility and cost-efficiency.

Offline AOI advantages include:

-

No need to interrupt production lines

-

Ability to test multiple product types with one system

-

Lower investment than dedicated inline machines

-

Great for R&D, prototyping, or small-batch runs

In other words, it’s ideal if your factory produces varied products or needs spot checks without slowing down mass production.

Key Features You Should Look For

When selecting offline AOI inspection equipment, pay attention to:

-

High-resolution cameras for micro-defect detection

-

Deep learning algorithms for defect classification

-

Customizable inspection templates

-

User-friendly software interface

-

Data output integration with MES or ERP systems

These features ensure your AOI system can catch everything from soldering defects to scratches, cracks, and missing components.

Cost Benefits of AOI Systems

Sure, the upfront investment might feel big, but the return on investment (ROI) is undeniable. Offline AOI helps manufacturers:

-

Reduce defect escape rates

-

Lower rework and scrap costs

-

Save labor costs from manual inspections

-

Improve customer satisfaction with consistent quality

Why Work with Chinese Suppliers?

When sourcing offline AOI inspection equipment, many U.S. and European companies choose Chinese manufacturers because they offer:

-

Competitive pricing

-

Advanced technology adoption (AI + machine vision)

-

Customization services

-

Strong global export experience

👉 Companies like Kunshan Jiexiang Industrial Equipment Co., Ltd. deliver cutting-edge AOI solutions trusted by global leaders in electronics and new energy industries.

If your factory values quality, efficiency, and flexibility, offline AOI inspection equipment is a smart investment. It’s not just about detecting defects—it’s about building a reputation for zero-defect manufacturing.