What Problems Can a Multifunctional Deburring Machine Solve in Precision Manufacturing?

2025-08-05

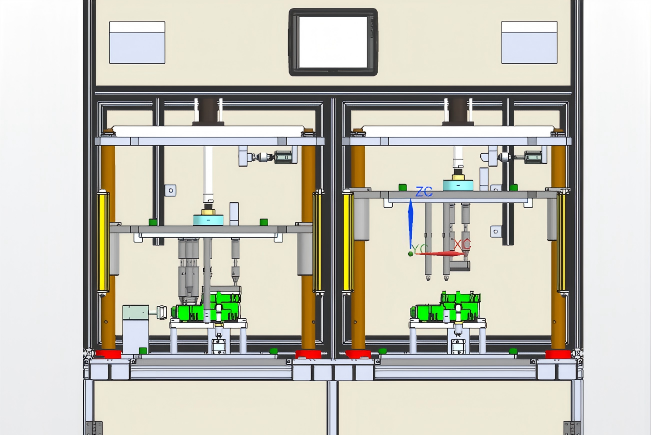

In the highly competitive world of precision manufacturing, even the smallest imperfection can lead to product failure, rework, or customer dissatisfaction. That’s why more companies are turning to multifunctional deburring machines to address common production problems.

So, what specific issues can these machines help solve? Let’s take a closer look.

1. Inconsistent Surface Finishes

Uneven surfaces caused by manual deburring can lead to poor product aesthetics and assembly problems. A multifunctional deburring machine ensures a consistent finish across all parts, improving quality and reducing rejects.

Plus, the machine is designed to handle various surface textures, whether you're working with stainless steel, aluminum, or other metal alloys.

2. Safety Hazards from Sharp Edges

Sharp burrs are more than just annoying—they’re dangerous. Workers handling parts with sharp edges are at risk of injury, and end-users may experience cuts or discomfort.

Automated deburring machines effectively round off edges and remove burrs, helping manufacturers meet ISO safety standards and enhance workplace safety.

3. Poor Product Assembly

Ever had trouble fitting parts together during final assembly? That’s often due to tiny burrs or uneven edges. With a multifunctional deburring machine, manufacturers can achieve:

-

Tight tolerances

-

Smooth fits

-

Improved product reliability

This means fewer errors and reduced time spent on troubleshooting.

4. Excessive Labor and Downtime

Manual deburring is time-consuming and labor-intensive. It also creates bottlenecks in production lines.

By switching to an automated deburring solution, companies can:

-

Increase throughput

-

Free up labor for other tasks

-

Reduce operational costs

Let’s face it, nobody likes paying for rework or delays, right?

5. Surface Defects Affecting Coating or Welding

Burrs and residues interfere with downstream processes like:

-

Powder coating

-

Painting

-

Welding

A multifunctional deburring machine prepares parts for post-processing, ensuring better adhesion and bonding.

Why Are More Global Buyers Choosing Chinese Deburring Machine Manufacturers?

China has emerged as a global hub for industrial automation, offering:

-

High-performance multifunctional deburring machines

-

Affordable prices with flexible customization

-

Strong R&D capabilities

-

After-sales support with fast parts availability

Suppliers like Kunshan Jiexiang Industrial Equipment Co., Ltd. are leading the way with tailored solutions for manufacturers in the U.S., Europe, and Southeast Asia.

When Should You Upgrade Your Deburring Process?

If you’re experiencing:

-

High rejection rates

-

Low production efficiency

-

Surface quality complaints from clients

…then it’s probably time to upgrade to a multifunctional deburring machine. The ROI is often visible within a few months through improved product quality and reduced labor.

Deburring is not just an afterthought—it’s a critical step in precision manufacturing. Investing in the right multifunctional deburring machine can solve a wide range of production problems, enhance efficiency, and boost customer satisfaction.

If you’re looking for a reliable Chinese supplier, start with companies that offer customized automation solutions backed by years of experience.