Is CCD Detection Equipment the Future of Industrial Quality Inspection?

2025-09-02

In manufacturing, every detail matters. A small scratch on a PCB, a missing component in a battery pack, or a tiny misalignment in an automotive part can cause costly failures. For many factories, manual inspection just isn’t enough anymore. That’s why CCD detection equipment is quickly becoming the go-to solution for companies that want to stay ahead.

What Makes CCD Detection Different?

Unlike traditional inspection methods that rely heavily on human eyes, CCD detection equipment uses high-resolution cameras and advanced algorithms to automatically detect defects.

Here’s why that’s important:

-

Consistency: Cameras don’t get tired or distracted.

-

Speed: Every product can be inspected in seconds.

-

Accuracy: Even micro-level defects can be spotted.

With these benefits, manufacturers are moving from sampling inspection to 100% full inspection without slowing down production.

Why Manual Testing Is No Longer Enough

Let’s be honest—manual testing has its limits:

-

Workers get fatigued after long shifts.

-

Subtle defects are easy to overlook.

-

Labor costs continue to rise.

In industries like electronics, semiconductors, and lithium batteries, defects are not just inconvenient—they can destroy brand reputation. That’s why more companies are choosing CCD inspection machines to guarantee product quality.

CCD Detection and Competitiveness

Think of CCD detection equipment as more than just a quality tool. It’s a competitive advantage. By ensuring consistent quality, you can:

-

Reduce rework and scrap costs

-

Meet international quality standards

-

Win trust from global customers

In today’s market, companies that adopt advanced quality control systems often secure better contracts and long-term clients.

Why Partner with a Chinese Manufacturer?

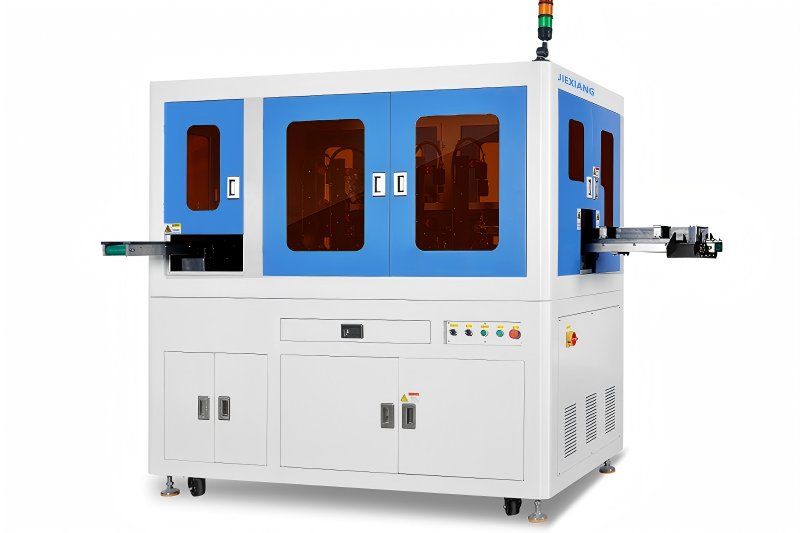

China is a global hub for industrial inspection solutions. Chinese CCD detection equipment suppliers, such as Kunshan Jiexiang Industrial Equipment Co., Ltd., deliver:

-

Customizable CCD inspection machines

-

Affordable solutions compared to Western brands

-

Integration with factory automation systems

-

Strong after-sales support for overseas clients

This combination of cost-effectiveness and advanced technology makes Chinese suppliers a top choice for global buyers.

So, is CCD detection equipment the future of quality inspection? The answer is a clear yes. Factories that embrace CCD technology improve efficiency, guarantee accuracy, and gain an edge in the global supply chain.

If you want to compete on a bigger stage, it may be time to replace repetitive manual checks with fully automated CCD inspection systems.