How Can CCD Detection Equipment Improve Quality Control in Your Factory?

2025-08-26

Every manufacturer wants to improve quality control, but achieving 100% defect-free production is no small challenge. Manual inspection methods often fail to keep up with modern production demands. So, how can CCD detection equipment transform your factory’s quality control?

The Role of CCD Detection in Quality Control

CCD detection equipment works by using high-resolution cameras, optical sensors, and intelligent software to automatically identify defects. Whether it’s scratches, cracks, misalignments, or missing components, CCD systems can find issues that human eyes often miss.

This makes them ideal for industries like:

-

PCB and electronics manufacturing

-

Lithium battery production

-

Automotive components

-

Precision machining

From Sampling to 100% Inspection

Traditional manual inspection usually relies on sampling, which means defects can slip through. In contrast, CCD detection enables:

-

100% product coverage

-

Non-contact inspection without damaging parts

-

Rapid detection in high-volume production

By upgrading from sampling to full-scale automated inspection, factories significantly reduce defect escape rates.

Efficiency Gains with CCD Systems

Factories using CCD detection report:

-

Faster cycle times

-

Reduced reliance on manual labor

-

Lower operational costs

-

Real-time defect feedback for process improvement

This efficiency translates directly into higher profitability and better customer satisfaction.

Enhancing Enterprise Competitiveness

Global buyers often compare suppliers not only on price but also on quality consistency. A factory with CCD detection equipment can confidently promise:

-

Higher yield rates

-

Reliable delivery schedules

-

Compliance with strict quality standards

This strengthens the factory’s position when competing in global supply chains.

Why Choose a Chinese CCD Detection Equipment Supplier?

China has become a leading hub for industrial automation equipment. Many overseas buyers partner with Chinese CCD detection equipment manufacturers because they offer:

-

Customizable designs for unique production needs

-

Integration with MES/ERP systems

-

Affordable yet advanced solutions

-

Professional after-sales service

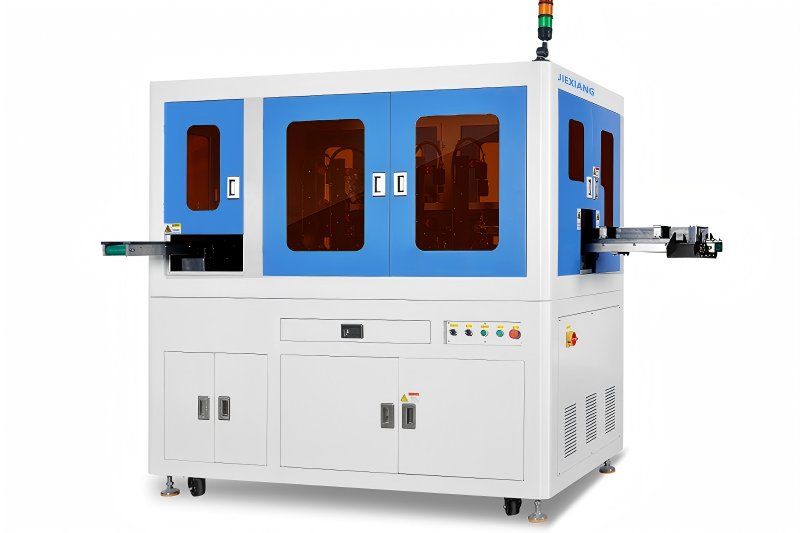

For example, Kunshan Jiexiang Industrial Equipment Co., Ltd. provides CCD inspection machines that meet international standards while ensuring cost-effectiveness.

If you’re serious about improving quality control and efficiency, CCD detection equipment is no longer optional—it’s a necessity. By upgrading your inspection process, you not only prevent costly defects but also strengthen your reputation as a trusted supplier in the global market.