What Are the Main Benefits of Using Online 2D AOI in Electronics Manufacturing?

2025-09-27

Electronics manufacturing has changed dramatically in the past decade. Components are smaller, PCB designs are denser, and customer expectations are higher. Traditional manual inspection just can’t keep up anymore. That’s where online inspection equipment 2D AOI comes in. It provides manufacturers with a reliable way to maintain quality without slowing down production.

So, what are the main benefits of adopting online 2D AOI? Let’s break it down.

Faster Inspection Without Slowing Production

In fast-moving production lines, time is money. Online 2D AOI is installed directly on the production line, meaning every PCB is inspected in real time. No need to stop the conveyor, no need for manual sampling. This continuous workflow helps factories achieve higher throughput while maintaining consistent quality.

Think about it this way: instead of having inspectors check boards one by one, the AOI system is like having a hundred eyes watching every detail at lightning speed.

Improved Accuracy and Reliability

Human inspectors are skilled, but let’s face it—staring at PCBs for hours can lead to fatigue and mistakes. Online 2D AOI eliminates this issue by relying on high-resolution cameras and advanced algorithms. It can detect tiny defects like solder bridges, missing parts, or polarity errors that a person might overlook.

The result? More accurate inspections, fewer errors, and more reliable products reaching the market.

Cost Savings Through Defect Reduction

Catching defects early is one of the biggest benefits of AOI. Online 2D AOI systems flag issues immediately, preventing defective boards from moving further down the production line. This reduces rework, scrap, and wasted materials.

And here’s the kicker: fewer defects mean happier customers and fewer warranty claims. Over time, these savings add up significantly, making AOI a smart investment.

Real-Time Feedback for Process Control

Online AOI isn’t just about catching problems—it’s also about improving processes. When an AOI system detects recurring defects, it gives engineers valuable data to adjust machines, soldering parameters, or placement accuracy.

This real-time feedback loop allows manufacturers to continuously improve quality and efficiency. In other words, AOI doesn’t just find problems—it helps fix them at the root.

Enhanced Competitiveness in the Market

In today’s global market, manufacturers need every advantage they can get. Adopting online inspection equipment 2D AOI signals to clients that your factory is serious about quality. This can help win contracts, attract new business, and strengthen your reputation.

After all, buyers want assurance that the products they’re sourcing will meet high standards. AOI provides that assurance.

Flexibility for Different Manufacturers

One of the great things about online 2D AOI is its flexibility. Large factories use it to handle high-volume production, while smaller factories adopt it to gain a competitive edge. Whether you produce thousands of PCBs per day or smaller runs for niche applications, AOI can adapt to your needs.

And honestly, with electronics getting more complex every year, skipping AOI isn’t really an option anymore.

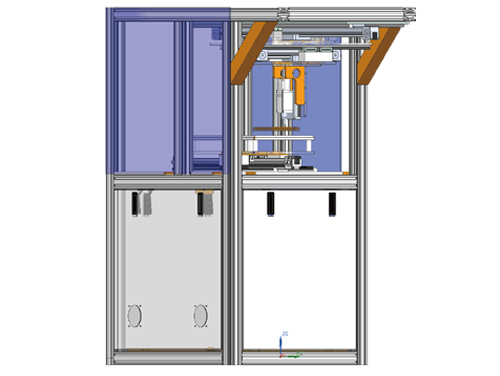

Choosing the Right AOI Supplier

The benefits of online 2D AOI are clear, but they depend on choosing the right equipment supplier. A strong supplier offers not only advanced hardware and software but also customization and after-sales support. Many buyers now prefer working with Chinese manufacturers and suppliers due to their ability to deliver high-performance AOI solutions at competitive prices. Companies like Kunshan Jiexiang Industrial Equipment Co., Ltd. are trusted partners in this field.

Online inspection equipment 2D AOI is a must-have for electronics manufacturers looking to stay competitive. From faster inspections and higher accuracy to cost savings and process improvement, the benefits are clear. Whether you’re a large-scale producer or a smaller operation, AOI technology can make a real difference in your bottom line.