What Is a Non-Standard Automatic Material Feeding Machine and How Does It Work?

2025-10-09

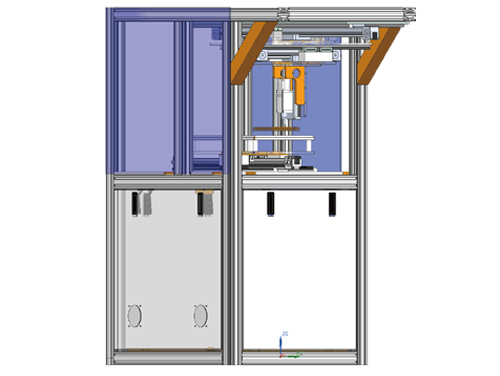

In modern manufacturing, efficiency and automation are key. A non-standard automatic material feeding machine is a specialized system designed to feed materials into production lines automatically, especially when standard feeding equipment cannot meet unique production requirements. But what exactly does “non-standard” mean, and how does this type of machine work?

What Does “Non-Standard” Mean?

The term non-standard refers to machines that are customized for specific production needs. Unlike regular feeders, which are designed for standard materials and sizes, non-standard feeders can handle unusual shapes, sizes, or materials. This makes them ideal for manufacturers who require flexibility and precision.

How Does a Non-Standard Automatic Material Feeding Machine Work?

The working principle is fairly straightforward:

-

Material Loading – Raw materials are placed into the feeding system.

-

Automation Control – Sensors and control systems ensure materials are fed at the right time and speed.

-

Delivery to Production Line – Materials are transported accurately to the production equipment without manual intervention.

This automated process reduces labor costs, minimizes errors, and improves overall production efficiency.

Why Manufacturers Choose Non-Standard Feeders

-

Flexibility – Can adapt to various production needs.

-

Efficiency – Continuous feeding without interruption.

-

Accuracy – Precise material positioning reduces defects.

Even for small or medium-sized factories, this technology can significantly improve productivity.

A non-standard automatic material feeding machine is not just a luxury—it’s becoming a necessity for manufacturers seeking efficiency and reliability. By automating material handling, businesses can focus on higher-value production tasks and maintain a competitive edge.