Why Should Manufacturers Switch from Manual Testing to CCD Detection Equipment?

2025-08-26

In modern manufacturing, efficiency and precision are the keys to success. Many factories still rely on manual testing methods, but manual inspection often leads to inconsistencies, human error, and higher labor costs. So, why should manufacturers switch to CCD detection equipment? Let’s explore the benefits.

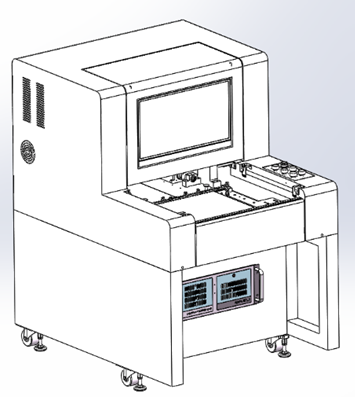

What Is CCD Detection Equipment?

CCD (Charge-Coupled Device) detection equipment is a vision-based inspection system. Instead of human operators performing repetitive checks, the system uses high-resolution cameras and image processing algorithms to automatically inspect every product in real time.

With CCD technology, companies can achieve:

-

Full automation of inspection

-

High-speed defect detection

-

Data-driven quality analysis

The Downsides of Manual Testing

Manual inspection has been used for decades, but it comes with limitations:

-

Fatigue and inconsistency from workers

-

Slower throughput for high-volume production

-

Difficulty detecting micro-defects

-

High labor costs

In industries like electronics, semiconductors, and lithium batteries, even the smallest defect can lead to product failure. That’s why relying on manual testing is increasingly risky.

How CCD Detection Improves Efficiency

With CCD inspection, manufacturers can:

-

Inspect 100% of products automatically

-

Run inspections 24/7 without breaks

-

Detect defects as small as microns

-

Collect real-time quality data for process optimization

This not only reduces defect rates but also frees up skilled workers for higher-value tasks.

Accuracy and Competitiveness

In today’s global supply chain, customers demand consistent quality. By adopting CCD detection equipment, manufacturers gain:

-

Zero-defect reputation

-

Faster delivery with fewer reworks

-

Improved compliance with quality certifications

Ultimately, this enhances competitiveness, especially when bidding for contracts with international clients.

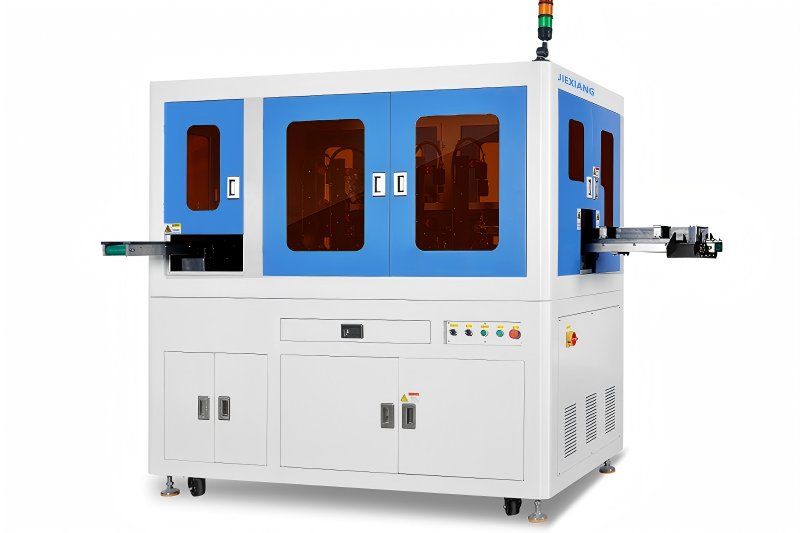

Why Source CCD Detection Equipment from China?

Chinese manufacturers have rapidly advanced in the field of vision inspection technology. Leading suppliers, such as Kunshan Jiexiang Industrial Equipment Co., Ltd., offer:

-

Custom-built CCD inspection systems

-

Competitive pricing

-

Strong after-sales support

-

Proven export experience in electronics, new energy, and semiconductors

Switching from manual testing to CCD detection equipment is not just about automation—it’s about staying competitive in a demanding global market. For manufacturers aiming to improve efficiency, accuracy, and long-term ROI, CCD inspection is the smart choice.